- HOME

- Products & Services

- Inspection

- SiC Latent Defect Expansion Inspection Device(UV-EVI:UV Expand Visualize Inspection)

Products & Services

SiC Latent Defect Expansion Inspection Device(UV-EVI:UV Expand Visualize Inspection)

SiC devices are gaining attention as energy-saving materials, but bipolar degradation has become a recent technical issue.

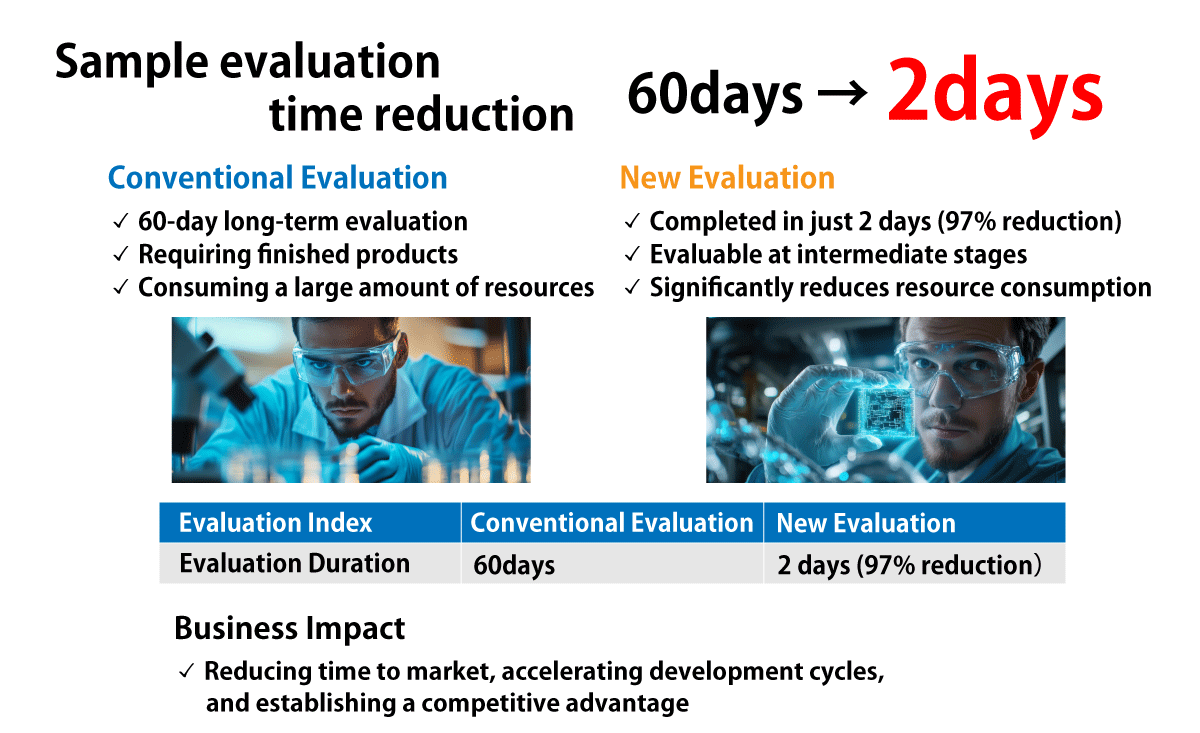

This phenomenon occurs when repeated current flow causes BPD defects within the substrate to expand, eventually leading to device failure. Latent BPDs are difficult to detect with standard inspections, and even when changing materials or device structures as a countermeasure, sample testing takes about two months, making rapid response challenging.

Therefore, we have developed a device that can reproduce bipolar degradation through UV laser irradiation and visualize latent defects at the wafer level.

This product is a joint development with ITES Co.,Ltd.

Purpose of inspection

We primarily envision its use in product development and research. It can replace sample evaluations that typically take two months with a process that only takes two days.

- Device Manufacturers: It is possible to confirm the impact of manufacturing process-induced stacking defects at various stages of device manufacturing. It supports both wafer size and chip size.

- Wafer Manufacturers: It allows for the verification of the impact of defects caused by substrate materials, epitaxial layer thickness, and impurity concentration at the wafer level.

- Both Device and Wafer Manufacturers: It enables the evaluation of the effects of ion implantation, such as protons and helium.

Features

UV Irradiation Expansion of BPD

- Expansion of BPD/stacking defects through UV laser irradiation is possible.

- Equipped with a proprietary uniform irradiation mechanism.

- The laser irradiation alignment mechanism supports both wafer-level and chip-level applications.

- The UV irradiation heater stage replicates the temperature environment in which the device will be used.

PL Inspection

- Expanded BPD/stacking defects can be observed in the substrate, substrate interface, buffer layer, and drift layer using our proprietary PL mechanism.

- PL inspection allows for automatic focusing with laser autofocus.

- Image processing algorithms enable the identification and classification of stacking defect locations (buffer layer, drift layer, substrate interface).

- Including a mapping function with coordinates of defect locations.

Specifications

Common Specifications

| Item | Details |

|---|---|

| Material | SiC |

| Material size | 150mm/200mm/Chip/Fragment |

| Handling | Manual placement |

| Machine size | Main Unit: (Width) 2060 x (Depth) 1360 x (Height) 2400 (mm) |

| Option | Heat Treatment Function (Defect Shrinkage) |

UV Irradiation

| Item | Details |

|---|---|

| Light Source | UV laser |

| Beam diameter | Φ2-5mm |

| Heater stage | ~200℃ |

| Single Item Sales | Available |

PL inspection

| Item | Details |

|---|---|

| Observation Method | PL Microscope (with Laser Autofocus) |

| Objective Magnification | 5x, 10x |

| Drawing Pixel Size | 4.6um×4.6um |

Visual Inspection of Semiconductor Wafers

Download a Document

The Next Dimension of Semiconductors: Exploring Advanced Packaging

Glossary

Related products

Documents

Contact Us

Please feel free to contact us.

SiC Latent Defect Expansion Inspection Device(UV-EVI:UV Expand Visualize Inspection)

Contact Us

Contact Us

Download documents

Download documents

Member services

Member services