Wafer Visual Inspection System

by Tokyo Electron Device

Bring innovation

to your semiconductor production line

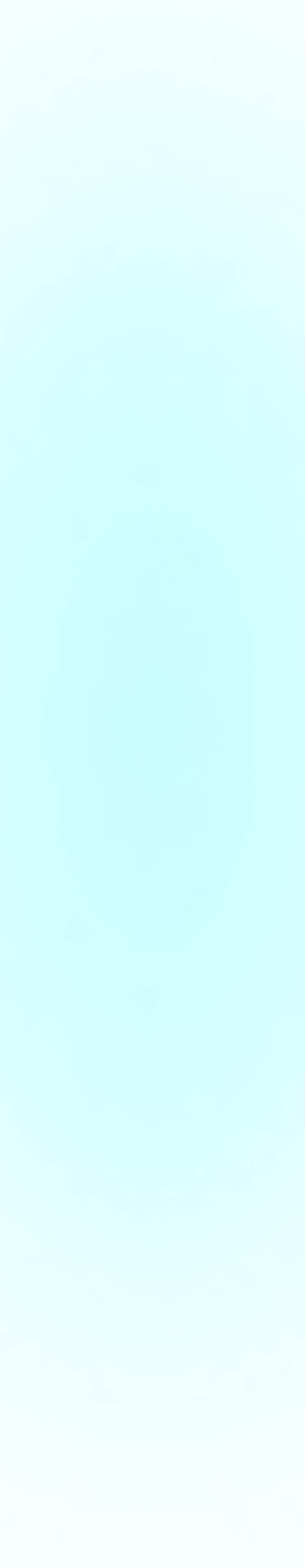

Are You Facing These Challenges?

Common Challenges

in the Field

- Want to automate visual inspection

in high-volume production lines - Need to automate microscope-based

sample inspection - Want to replace aging inspection

equipment

Are

You

Facing

These

Challenges?

Common Challenges

in Inspection

- Want to perform 100% inspection

with high throughput - Need to inspect front side, back side

and edge of

the wafer in a single

process for better efficiency - Want to automatically classify defect types and

use the data

to drive process improvement

Quality and

Efficiency

Tokyo Electron Device

offers the solution.

Our cutting-edge inspection

technology

effectively

addresses all of these issues.

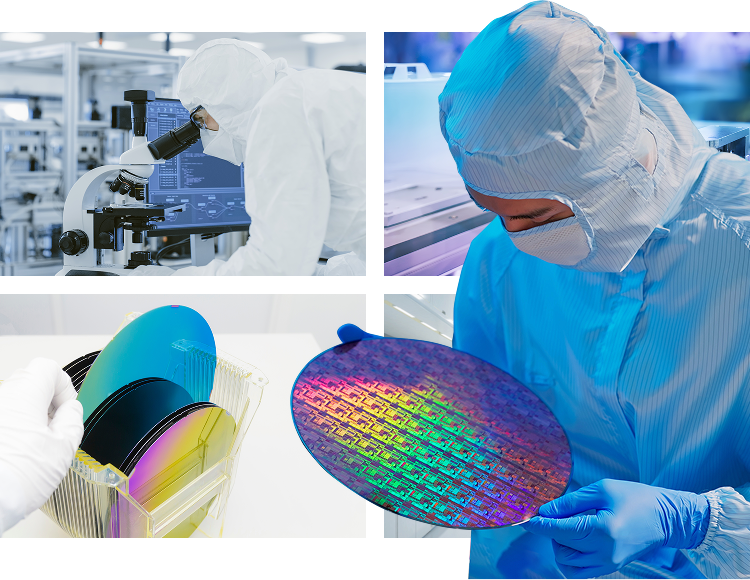

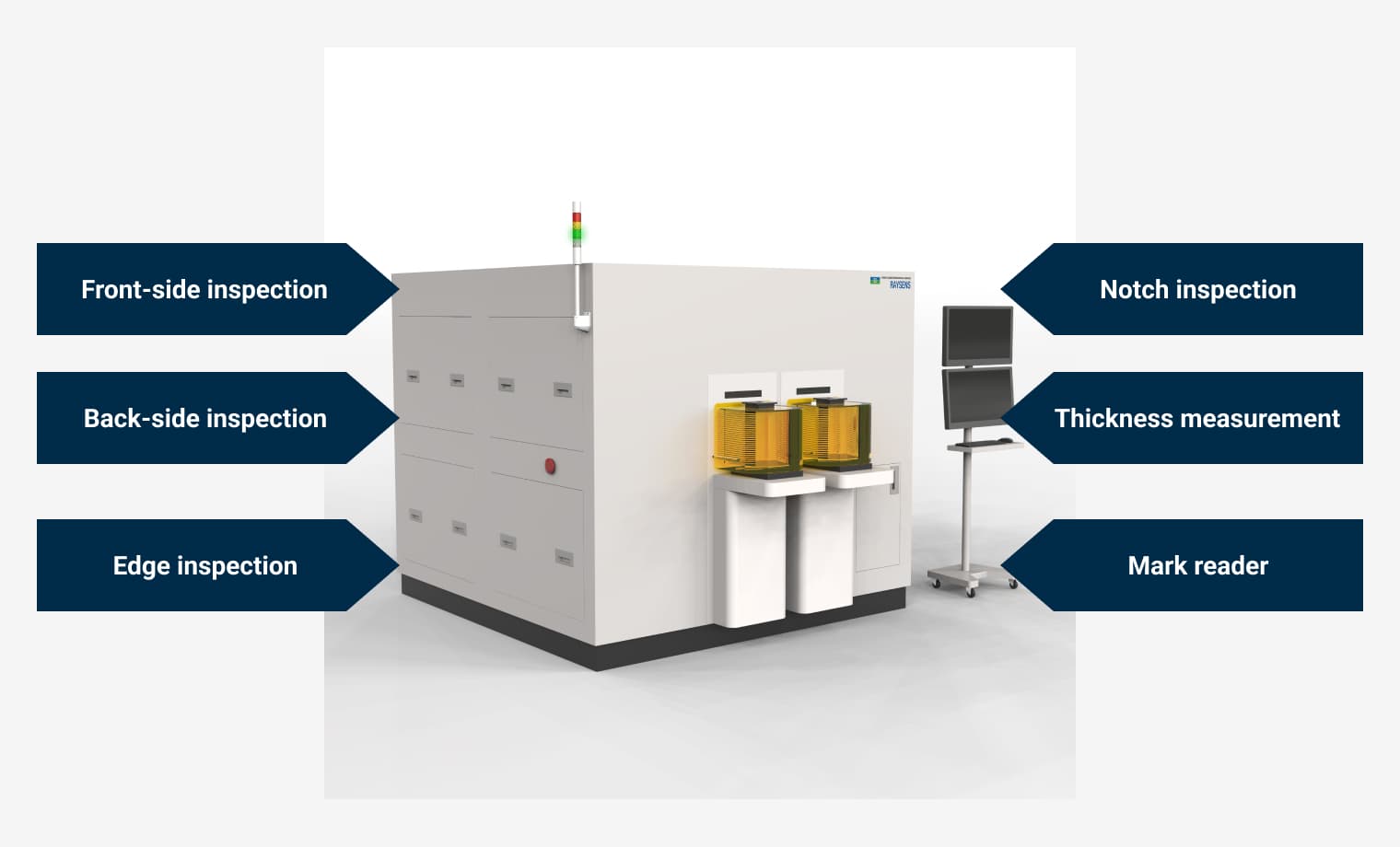

Wafer Visual

Inspection System

-

High-speed detection of submicron-level defects*40~120/wph

-

Multi-surface inspection (front, back, and

edge) with a single system -

Advanced image processing and AI for

defect detection and automatic

classification

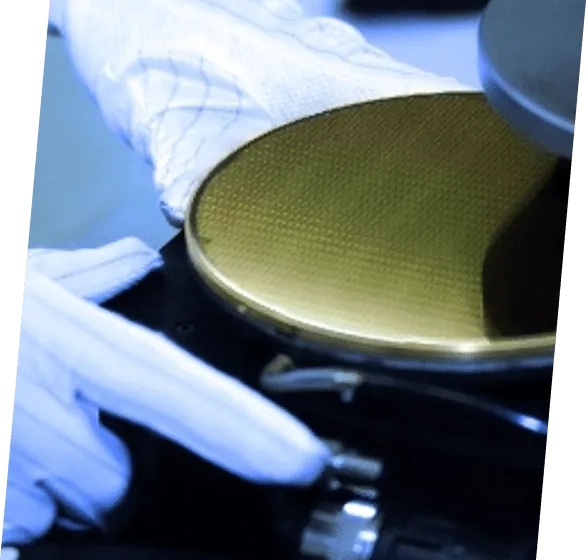

Three Key Technologies

for Solving Inspection Issues

Technology

Applicable Wafers for

Inspection

Wafer

Our system supports a wide range of materials, including silicon wafers, compound wafers, glass wafers, and mask blanks.

We perform defect inspection using optical

systems and image processing tailored to the specific characteristics and defects of each

material.

-

Si(8/12inch)

Main Applications of Wafers

Widely used in various semiconductors such as logic and memory devices, as well as interposers.

-

SiC(6/8inch)

Main Applications of Wafers

For power semiconductor devices

(e.g., MOSFETs, Schottky Barrier Diodes (SBD), etc.) -

Glass(8/12inch)

Main Applications of Wafers

Support and carrier

wafers,

and interposer substrates -

LT/LN(6/8inch)

Main Applications of Wafers

SAW devices, optical isolators,

and sensors -

GaN(6/8inch)

Main Applications of Wafers

Power semiconductors for high voltage and high current, lasers, and LEDs

-

InP(3/4inch)

Main Applications of Wafers

Optical communication devices such as laser diodes, and high-

frequency devices -

Mask Blanks(6inch)

Defects Subject to

Inspection

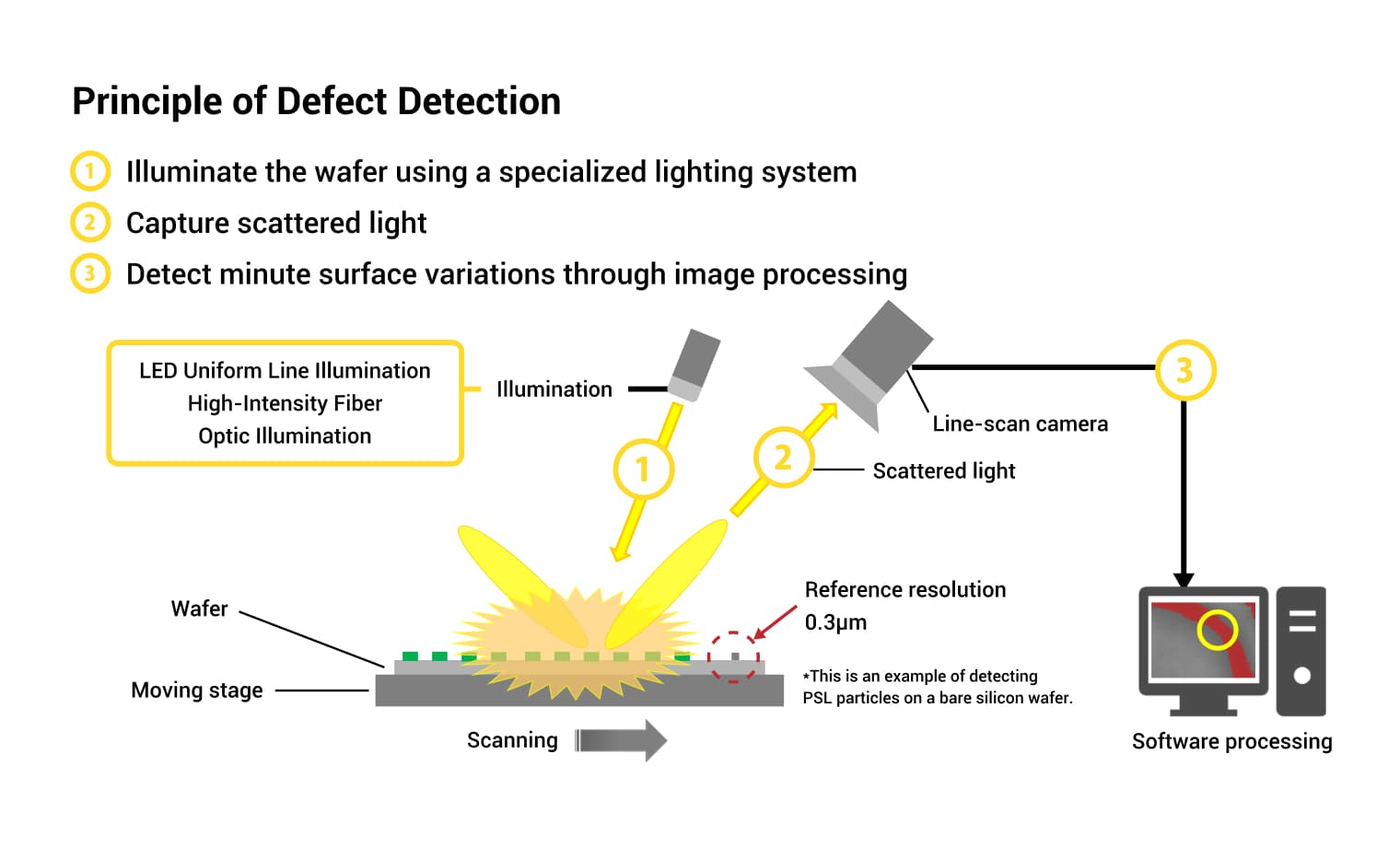

Defect

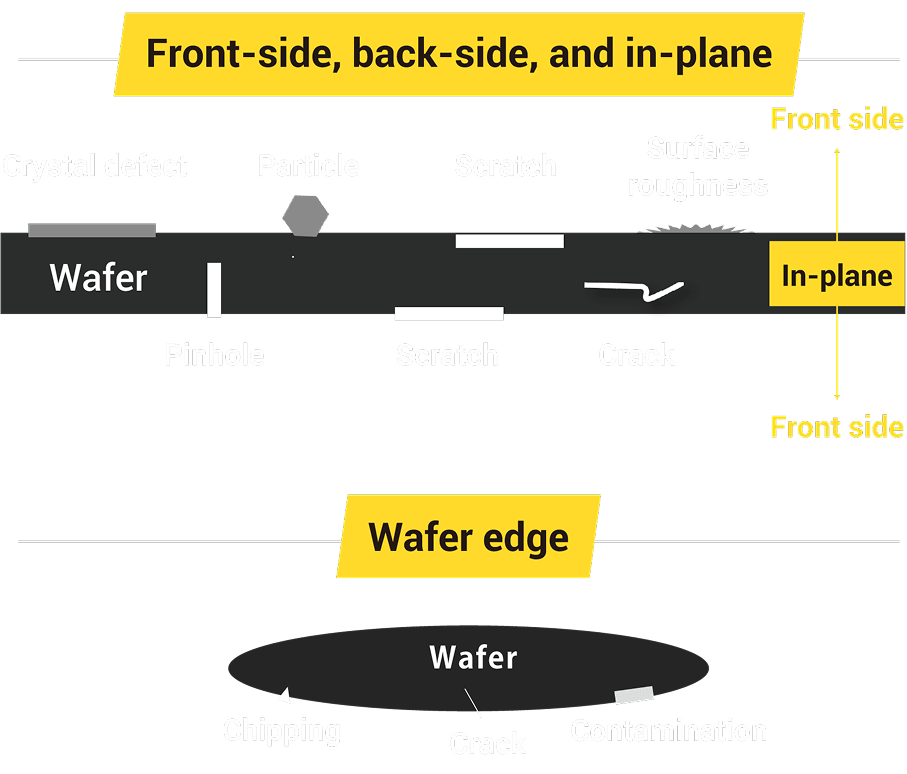

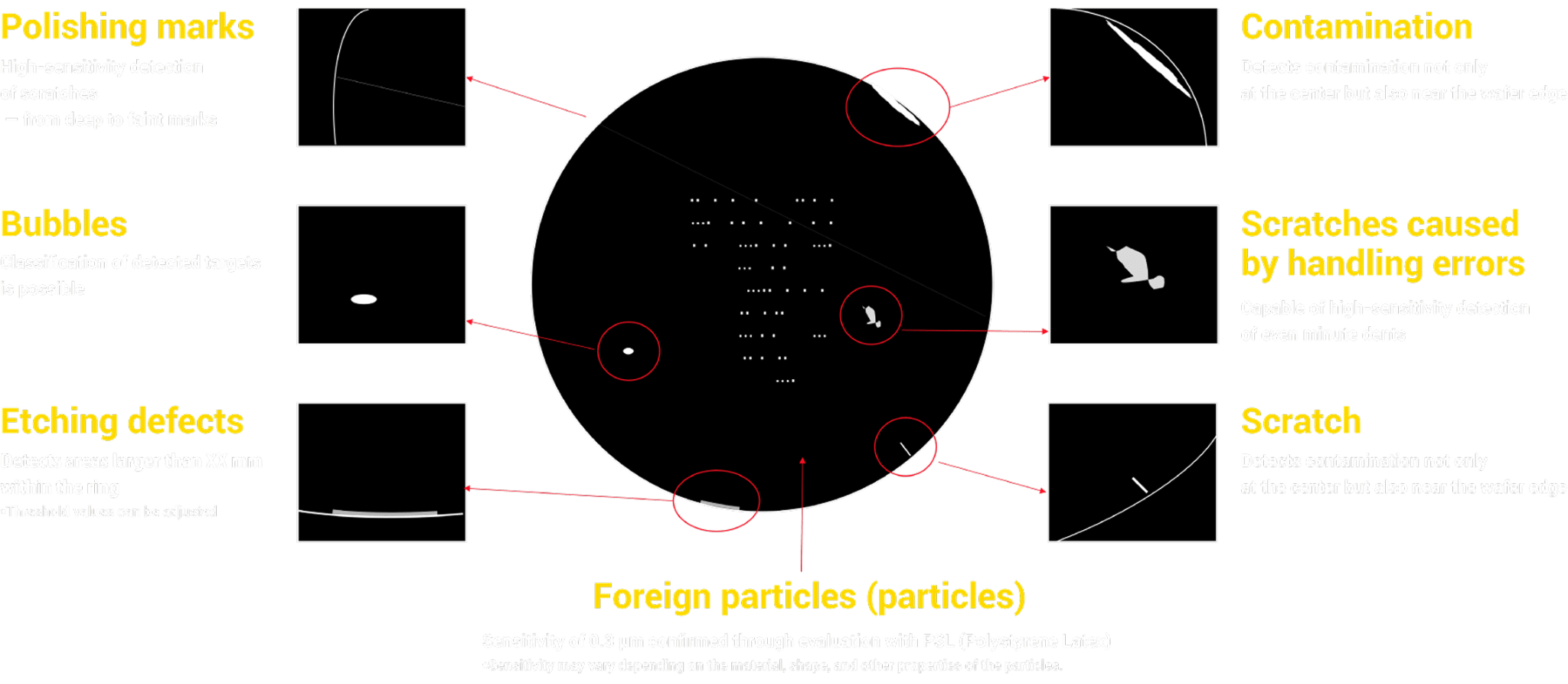

We inspect various types of defects shown in the diagram on the wafer’s front surface, in-plane,

back surface, and edge.

The primary target defect sizes range from submicron to several tens of microns.

List of Target Defects

| Category | Types of Defects to be Detected |

|---|---|

| Front surface / Back surface |

Foreign particles (Particles) |

| Contamination (Dirt) | |

| Scratches | |

| Dents (Dimples) | |

| Chips (Chipping) | |

| Cracks | |

| Crystal defects | |

| Pinholes | |

| Protrusions (Protuberances) | |

| Color non-uniformity | |

| Lithography defects (Litho defects) |

|

| Polish marks | |

| Grinding marks | |

| Thermal marks | |

| Haze | |

| Edge notch | Cracks / Chips / Contamination |

| Bonding surface | Voids |

Examples of Silicon and

Compound Semiconductor Wafers

Examples of Glass Wafers

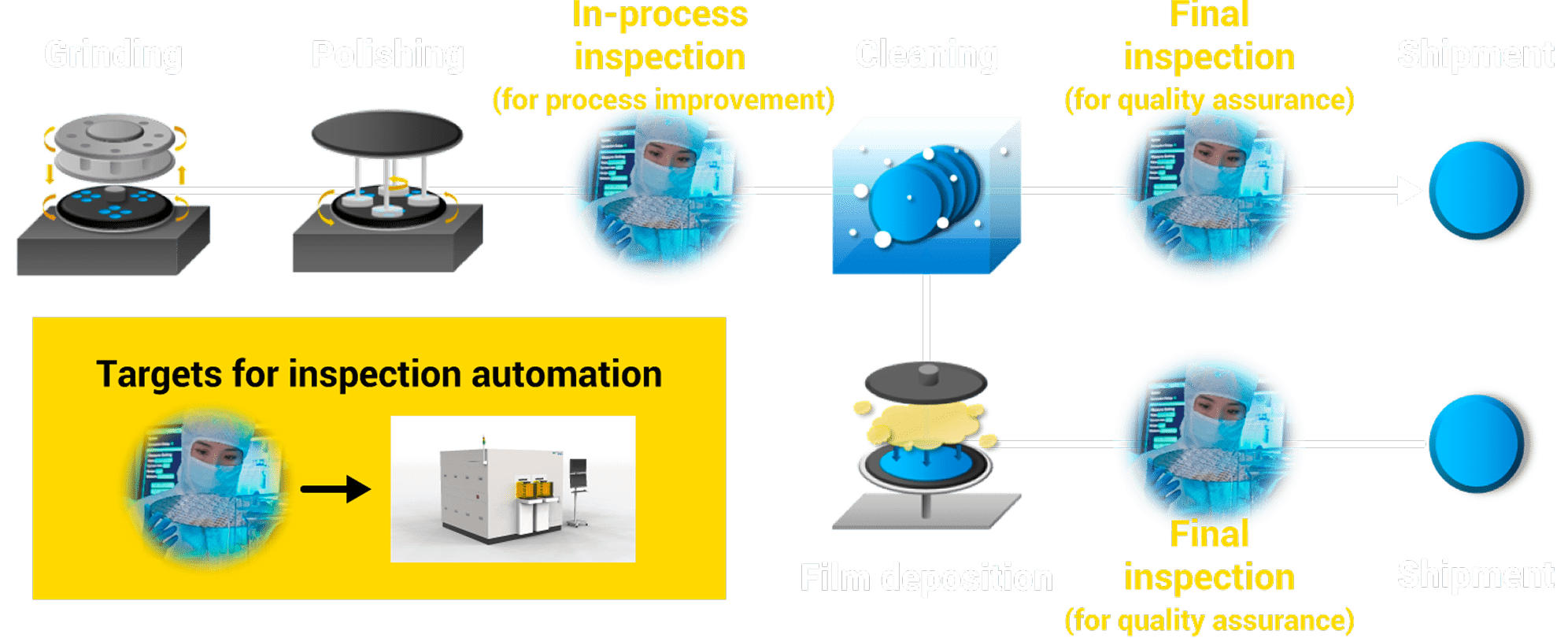

Example of a Wafer Inspection Process

Inspection Process

Inspection System Lineup

Line Up

We offer dedicated inspection systems tailored to specific inspection targets.

Each system is optimized—including inspection modules, optics, and image processing—to meet

your application needs and deliver a high-quality inspection environment.

-

Si wafer(6/12inch)

-

SiC wafer(6/8inch)

-

Glass wafer(8/12inch)

-

LT/LN wafer(6/8inch)

-

SiC latent crystal defect

-

Wafer Pattern Defect

Inspection Systems

Sample Evaluation Available

If you are facing inspection challenges, we offer sample evaluation using our in-house

test environment.

You can assess the feasibility of

inspection before moving forward with equipment implementation.

a Sample Evaluation

Download Materials for Free

-

01

Visual Inspection of Semiconductor Wafers

What You'll Learn from This

Guide:- ・Various types of wafer materials

- ・Wafer manufacturing processes and visual inspection

- ・Types of defects

- ・Categories of

inspection

technologies

Recommended For

Anyone interested in or facing challenges with the inspection of silicon (Si), compound semiconductors (SiC, GaN, LT/LN, InP), or glass wafers.

Recommended For

Anyone interested in or facing challenges with the inspection of silicon (Si), compound semiconductors (SiC, GaN, LT/

LN, InP), or glass wafers. -

02

The Next Dimension of Semiconductors:

Exploring Advanced Packaging

What You'll Learn from This Guide:

- ・Future trends in the market and technology

- ・Evolution of advanced packaging

- ・Solutions to wafer processing challenges

Recommended For

- ・Those who want to stay up-to-date on semiconductor market trends and advanced packaging technologies

- ・Professionals seeking solutions to challenges in manufacturing processes and wafer processing

- ・Individuals interested in high-speed, high-density manufacturing technologies

- ・Engineers and technical experts involved in next-generation semiconductor development

Recommended For

- ・Those who want to stay up-to-date on semiconductor market trends and advanced packaging technologies

- ・Professionals seeking solutions to challenges in manufacturing processes and wafer processing

- ・Individuals interested in high-speed, high-density manufacturing technologies

- ・Engineers and technical experts involved in next-generation semiconductor development

Feel Free to Contact Us

Start with a Trial!